Bottom-line results

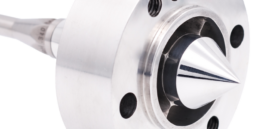

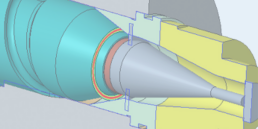

Leading extruders of thermoplastics and fluoropolymers look to B&H for precision quality extrusion tooling – and the ability to optimize tooling and output – before cutting metal.

B&H Flow Analytics™ eliminates costly “trial and error” tool design and lets you dial in performance exactly to your process and specifications – with real-time data.

B&H Flow Analytics quickly and efficiently identifies root causes and difficulties that ultimately can improve productivity and reduce costs.

Recent examples of customer return on investment include:

- $400,000 annual savings on a one-time $8,000 tooling investment by a Colorado extruding company.

- More than $50,000 in annual cost reductions as a direct result of a one-time $5,000 investment.

- A 40% increase in production capacity from an optimized crosshead design.

Start-to-finish support

We work closely with your engineering team as you bring your new tooling online and fine tune as necessary to ensure best-possible performance and results. We find our process consistently produces superior outcomes. Our commitment is to deliver exceptional results for every extrusion tooling project – large or small – standard or custom.