Extrusion Tooling Development

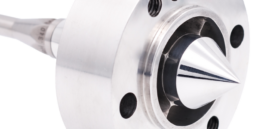

B&H Tool Company specializes in the development and manufacture of high and low temperature extrusion tips and dies. Thinner wall thicknesses, multiple lumens, closer tolerances, miniaturization – and new materials – are just some of the factors that impact extrusion tooling.

We provide designs, detail-engineers, prototypes and manufacture high-precision extrusion tooling – both single and multi-lumen – for medical device and other market manufacturers who require extremely tight tolerances and exceptional accuracy.

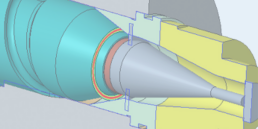

A proven delivery system

The polymer delivery system integral to B&H’s adjustable center cross- heads and inline dies assures concentricity, and outstanding laminar flow: material flows equally to the tip and die, producing uniform melt- stream velocity.

B&H offers a spiral deflector kit that enables extrusion tooling customers to modify their existing adjustable center crossheads to create transverse polymer orientation. For many materials and applications, this eliminates knit lines and improves burst strength.

B&H Extrusion Tooling features include:

- Axial, rotational tip adjustment for adjustable center crosshead extrusion

- Ability to extrude multiple configurations

- The ability to set material volume to your output rate

- Simple design with few parts, and a positive leak-free seal

- Reliable standard materials: 420 Stainless Steel, C-276 Hastel- loy® and 718 Inconel® (age-hardened)

- Tips, dies, breaker plates, adaptors, and heaters are available from single source