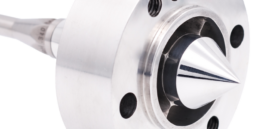

Micro Extrusion Crosshead

The BH25A Micro Crosshead with Spiral Deflector delivers break – through micro extrusion performance for microbore tubing, fiber optics and insulated fine wire. Compact and easy to handle, the BH25A Micro Crosshead extrudes:

- PEEK tubing with a product ID of .010” and OD of .015”.

- FEP insulated fine wire with an OD of .00471” and a core OD of .00157”.

Tested by major medical device manufacturers under production conditions, the BH25A demonstrated improvements in process stability of 30% or higher, and with tolerances never before achieved: less than .00010”. Testing also showed the BH25A Micro Crosshead with Spiral Deflector achieved exceptional ID/OD control, superior melt flow, and highly uniform material distribution.

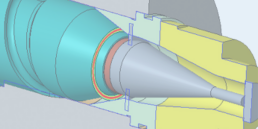

Two critical B&H design features prevent material degradation. The flow channel design of the BH25A Micro Crosshead — specifically the absence of hard edges and low-velocity pockets — effectively preserves the molecular weight of the material and helps in preventing mechanical degradation while optimizing melt flow and help prevent pyrogenic material degradation. The result is extraordinary concentricity, OD control, and finished surface quality. This low area crosshead creates a flow so thin, you can heat less – and because the material gradient is less, adjustment is always simpler and faster.

Whether the final product is bioabsorbable devices, communications electronics or a proprietary OEM application, customers using this innovative tooling report that these features provide a significant competitive advantage. Customers also note that the BH25A allows them to extrude materials they were unable to in the past.

Materials

The BH25A Micro Crosshead is manufactured in two versions with an adjustable center.

Both are appropriate for biomedical and other FDA/ USP Class VI applications.

A 420 stainless steel model provides optimum performance for thermoplastics; a Hastelloy head is specified for fluoropolymers.

The BH25A is engineered for quick assembly, disassembly, and cleaning.