Extrusion Heaters

B&H Tool provides a wide range of top-quality extrusion heaters to support our adjustable center and fixed center crossheads and in-line dies. First, we help you select the right type of heater to match your heat profile and extrusion requirements. Then, we customize heater performance for a perfect fit with your tooling.

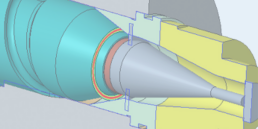

A Uniform heat profile is critical to the annular plastic extrusion process. Making sure that all exterior surfaces of the tooling are covered with heaters is one of our most important jobs. Heat and pressure, along with the material being extruded, are critical factors affecting the extrusion process. To perform properly, extrusion heaters must optimize laminar flow, and minimize both temperature and velocity gradients. B&H engineers take these issues very seriously. For more than 50 years, we have designed and developed extrusion heaters to match our customers’ specific applications.

Depending on the application and temperature profile required, we specify tubular band, mica band or cast-in extrusion heaters providing the ideal wattage, quality, price and service life.

We understand the complex dynamics of wattage, voltage, component quality and encapsulation. All B&H extrusion heaters fully envelop the crosshead. As a result, all B&H extrusion heaters optimize heat transfer efficiency, provide precise control over the heating process and eliminate the potential for dead spots.

Customers with constraints, such as limited space on the extrusion line, benefit from our collaborative approach. We work closely with your production and process engineers to determine the best-possible configuration. We design the extrusion heater and make certain its performance lives up to the tradition of quality craftsmanship that is behind all B&H extrusion heaters.

B&H is a premier aftermarket supplier of extrusion heaters offering a full product line for every standard crosshead we make – including many competitive crossheads.