STRATEGIES TO ELIMINATE EXTRUSION TUBING REJECTS & SCRAP

The Role of Area Draw Down Ratio and Draw Ratio Balance

For companies that extrude polymer tubing for medical use, stability

is the Holy Grail. Establish and maintain extrusion process stability,

and process-related quality problems disappear. When it comes to

optimizing performance within the die, there are tools for optimizing

extrusion process control that are simple to apply, and virtually foolproof.

Two of the most important calculations are area draw down ratio (ADDR),

and draw ratio balance (DRB).

Area draw down ratio is the ratio of the cross-sectional area of the

extruded plastic melt to the cross sectional area of the plastic in its final

product form, (tube, hose or insulation on a core, such as a wire or cable).

ADDR is the extent to which the plastic has been reduced in size to form

the part; it is a measure of the amount of stretching that occurs between

the exit of the die and the take-up. A larger ADDR enables faster production,

while a lower ADDR facilitates closer control of product dimensions. A low

draw down ratio process tends to be more stable than a higher one;

the key is to find the “sweet spot” that optimizes the balance between

the two. Figure 1 illustrates different values of the ADDR.

Figure 1, Illustration of Area Draw Down Ratio

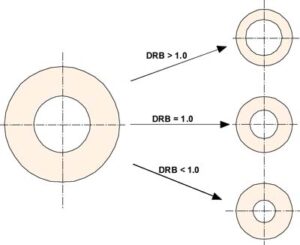

Draw ratio balance (DRB) is the diameter ratio of the die and tip divided

by the diameter ratio of the tubing. When the DRB equals one, the annular

shape of the tubing is the same as the annular shape of the tooling.

When the DRB is greater than one, the ID of the tubing relative to the

OD will be greater than the ID of the tooling (tip diameter) relative to the

OD (bushing diameter). This is illustrated in figure 2. For a stable tubing

extrusion process, the DRB should be equal to or greater than one.

Figure 2, Illustration of Draw Ratio Balance

Smiths Medical, a leading provider of medical devices, located in Tijuana,

Mexico operates multiple extrusion lines, on a 24/4 basis. The lines

extrude PVC, nylon, polypropylene and polyethylene for disposable

anesthesia berating circuits, catheters for epidural and tracheal use and

patient monitoring systems. Tolerances must be held to ±0.003.”

Manuel Castillo, Extrusion Engineer, joined Smiths Medical in April 2008

and took responsibility for process control and improvement of extrusion

performance and stability. A process control expert with more than 12 years

experience in sheet and tube extrusions, Mr. Castillo’s former post was with

another medical company, where he managed the extrusion department

from the process engineering side.

“When I joined the Smiths team,” he explains, “there was a big opportunity

to tighten control over the extrusion process. Seven out of ten production

orders were being rejected because they did not meet specifications. And it

was all related to issues with extrusion instability.”

Mr. Castillo used a four-point process to address those issues. “We began,”

he says, “by revalidating our portfolio of extruded tubes for uniformity.”

This involved approximately twenty codes, with each code representing

one product. “Using tools provided by B&H Tool Company (San Marcos, CA),

we changed our ADDR from 4:1 to 2:1 and immediately gained greater

dimensional stability.”

Tube drawings were then reviewed to clarify product dimensions.

“For example,” he explains, “tube diameters were referencing values

of a laser measuring device and the product spec. This created confusion

for operators.”

“We also optimized the land length to control the melt in the die,”

adds Castillo. “I always follow resin manufacturers’ recommendations,

and they usually recommend a 10:1 land length for PVC resins. Since

PVC is one of our higher runner materials, there’s always the opportunity

to improve land lengths. I will say, however, that instead of having a

10:1 land length individually calculated for every PVC tube, it’s preferable

to have a standard land length for the majority of the tooling. This allows

processors to use existing pins and dies for any new tube coming

into production.”

“This is possible – and highly beneficial – if the ADDR and DRB rules

are met. And it is another reason why the B&H calculators are so vital

to stabilizing – and optimizing – the extrusion process.”

Optimizing the extrusion process has produced immediate and dramatic

effects. “After the improvements were made, no production order has

been rejected,” says Castillo. Scrap has also been reduced dramatically.

“The use of the B&H internet tooling calculator was invaluable in getting

us to where we are today,” he explains. “In previous times, I had to

resolve these issues in other ways. Clearly, the ability to use the ADDR

and DRB for the different materials and tube dimensions we work

with is a huge advantage.”