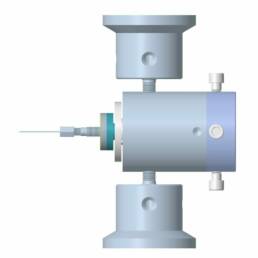

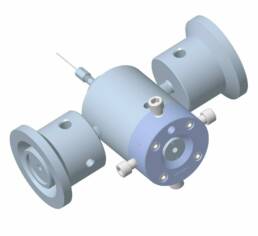

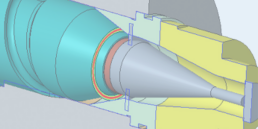

Multi-Layer Crossheads

B&H adjustable center, multilayer crossheads can be designed for any of your co-extrusion applications, including wire and cable, medical tubing, irrigation tubing and industrial tube, hose & pipe. B&H Multi-Layer Adjustable Center Crosshead features include:

- Axial, rotational tip adjustment while extruding

- Simple design with minimal parts

- Positive leak-free sealing

- Multiple mechanical feature options for flow distribution and wall control ability to assure balanced laminar flow, precisely regulate layer control, reduce material degradation, and optimize dimensional stability (on each layer)

The days of compensating for uneven flow on each layer during the extrusion process are over – due to our technical resources. Operators no longer need to adjust each layer on the fly. With computational fluid dynamic (CFD) analysis, BHT’s team of designers design internal components as a function of layer output and polymer rheology. The process becomes a matter of dialing the total wall thickness as opposed to compensating for uneven flow at the layer level.

- Outstanding end-product quality

- Can extrude high/low temperature thermoplastics and fluoropolymers

- Immediate, in-stock spare parts availability

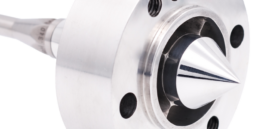

Materials

For low temperature applications, we use 420 Stainless Steel, heat-treated to RC52. For high temperature applications, our engineers specify C-276 Hastelloy® because it is corrosion-resistant and assures a long, trouble-free service life.