Fine-tune tool performance first

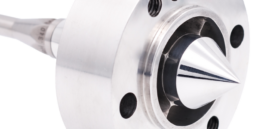

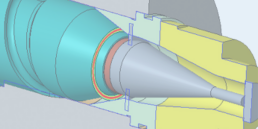

Take a closer look at polymer flow and extrusion head performance – without costly trial and error. Now you have the ability to see inside tooling to achieve the optimal head design for your target output rate and specific rheology.

B&H Flow Analytics ™ brings together proven methodology, technology and engineering expertise in a collaborative process – as a valuable extension of your process engineering capabilities.

Fine tune flow, hold higher tolerances, design for improved throughput with less waste. See for yourself with real-time data. Whether you need standard or custom extrusion tooling, get it right from the start with B&H Flow Analytics.

Dial in performance

Leading extruders of thermoplastics and fluoropolymers look to B&H for precision quality extrusion tooling – and the ability to optimize tooling – before cutting metal. See for yourself with real-time data. B&H Flow Analytics quickly and efficiently identifies root causes and difficulties related to:

- Surging and output issues

- Dimensional variation

- Material degradation

- Knit lines and appearance issues

- Problems not addressed by manuals or material spec sheets

B&H Flow Analytics™ includes a detailed evaluation of operations and material handling up and downstream of the extrusion operation, extruding equipment, screw geometry, dies, packaging and all relevant process metrics – particularly temperature profiles at critical junctures.

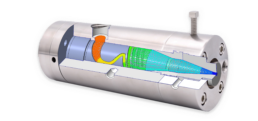

Our goal is to provide an efficient, comprehensive and cost-effective process for developing high-performance extrusion tooling design. It’s a process that has produced positive results and proven benefits including:

-Improved end-product quality

-Increased process stability

-Reduced scrap