Co-Extrusion Tooling Stripping Attachment

Striping has historically been used to add functionality, provide identification, and improve product aesthetics. For example, medical tubing with barium stripes are widely used for x-ray imaging. Working with multi-strand wire or cable configurations is easiest, and safest, when material is striped. And striped wire in consumer products have long been used to improve appearance, simplify assembly, or add functionality.

Today, co-extrusion striping has replaced most older and less efficient methods, and co-extrusion tooling is the technology of choice for most applications.

B&H specializes in innovative striping solutions. Whether your application is tracer wire, machine tool wire, appliance wire, blasting wire, cathodic protection, or other products, we can help you identify the striping attachment and related tooling that’s best for your application. We can assist with the design, development and testing of a custom solution for your striping requirement.

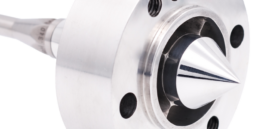

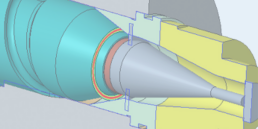

B&H Tool offers a cost-effective extrusion striping attachment for the co-extrusion of a single, dual, triple or “quad” stripe.

The B&H extrusion striping attachment installs quickly between the die holder and barrel body. It is compatible with all adjustable center crossheads and in-line dies used or insulating wire, jacketing cable, and extruding a medical or industrial tube.

With the attachment the stripe to be embedded in a tube or jacket, or extruded on the outside. Striping attachments are available for low temperature and high temperature applications – and can be retrofitted to existing B&H crossheads and in-line dies or purchased with new assemblies. An extended range core tube can be supplied where added length is needed.