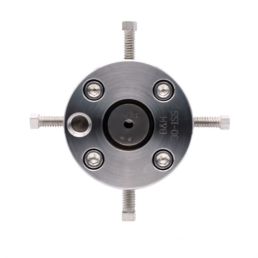

Adjustable Center Crossheads

Adjustable center crosshead assemblies provide three critical functions:

- Die adjustment

- Flow distribution

- Tip adjustment

B&H manufactures a wide range of precision adjustable center crossheads for a variety of industrial applications. B&H adjustable center crosshead assemblies include:

- Axial, rotational tip adjustment while extruding

- Simple design with minimal parts

- Positive leak-free sealing

- Multiple options for flow distribution

Leading companies look to B&H Tool for expert design and optimized standard and custom engineered extrusion tooling products. Consider the benefits of dialed-in tooling performance

- Extrude high & low temperature thermoplastics & fluoropolymers

- Balanced laminar flow

- Reduced material degradation

- Optimized dimensional stability

- Less scrap

- Reduced down-time

- Outstanding end-product quality

Optimizing Flow Distribution for Adjustable Crosshead Assemblies

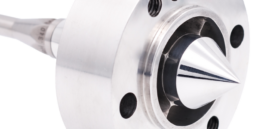

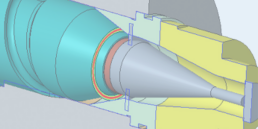

The exceptional design characteristics of B&H deflectors optimize laminar flow and concentricity, while assuring outstanding crosshead performance. B&H offers three major types of deflectors: high-volume, low-volume and spiral deflectors. B&H spiral deflector technology was developed to create transverse orientation of the plastic inside the crossheads. The result is increased burst pressure and the elimination of knit lines.

Spiral Retrofit

We make it easy to retrofit your existing B&H crossheads to gain the advantages of advanced spiral deflection. With this simple upgrade, you can continue to use your existing tooling. Our Spiral Deflector Upgrade Kit includes a deflector, barrel body, core tube, wedge ring, and a body heater customized to the crosshead.

Maintaining Temperature Consistency

All B&H adjustable center crosshead assemblies come with custom heaters and thermocouples. This provides a highly consistent heat profile on extruded material, and prevents crystallizing, material degradation, residual deposits, and defects.