Technology guided by 50 years of experience.

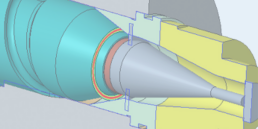

B&H Tool specializes in performance-driven annular die extrusion tooling using Computational Fluid Dynamic analysis (CFD) to improve standard and custom crosshead die designs and output. Leading companies look to B&H Tool as a single resource for expert design, optimized extrusion tool performance and manufacturing.

Our collaborative approach enables your engineering team to efficiently leverage B&H Tool expertise. Our proven comprehensive approach allows development work to be completed in substantially less time and less risk than conventional methods.

Standard or custom design, B&H expertise and Flow Analytics enable us to provide product solutions that consistently deliver greater reliability with higher performance and predictability than “one-size fits all” tooling.

Proven expertise

From thermoplastics to silicone, and fluoropolymers, we understand how pressure and shear can impact material being extruded – and how tooling can be optimized to control these and other factors.

Whether it’s a simple sketch or sample tool set, B&H Tool offers extensive design expertise and production resources for a comprehensive, value-added solution. And we continue to work closely with your engineering team as you bring new tooling online and fine tune as necessary to ensure best-possible performance and results.

Our 50+ year reputation is founded on a collaborative process that consistently produces superior outcomes. Our commitment is to deliver exceptional results for every extrusion tooling project – large or small – standard or custom.